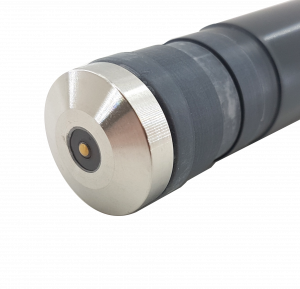

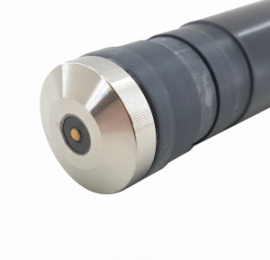

Online, continuous Peracetic Acid Analysers, Peracetic Acid Monitors, Peracetic Acid Meters and Peracetic Acid Controllers make up the PeraSense range which utilises the very latest and best peracetic acid sensors available in the world today. It is a membraned device which uses no reagents, is extremely stable, and has reduced maintenance and reduced whole life costs.

The PeraSense peracetic acid sensors, which give a peracetic acid measurement in ppm or mg/l, and a range of flow cells, are available with different peracetic acid controllers giving you the same great performance with different communication, display and control options. With the PeraSense range of peracetic acid analysers, you get everything that you need – and nothing that you don’t.

The PeraSense Peracetic Acid Monitor is used in many applications requiring the measurement of peracetic acid concentration simply for peracetic acid monitoring or peracetic acid dosing control.

In most situations the PeraSense analyser is able to control the dosing of CH3CO3H by adjusting flow rates, pump rates, or valve positions automatically to maintain the peracetic acid set-point. Automatic dosing can significantly reduce reagent costs, and increase the level of control.

In addition to the state of the art amperometric peracetic acid sensor, the PeraSense range of controllers has all the functionality that you need. Choose from the CRONOS® or CRIUS® controller to give you the highest quality peracetic acid monitor, with all the functionality you need, at the lowest price possible. This means that you pay for everything you need, and nothing you don’t, without sacrificing the quality of measurement.

- Amperometric sensors – continuous online peracetic acid ppm measurement

- No chemical reagents – lower cost of ownership

- Stable and reliable – excellent process control

- Suitable for all potable and process waters including sea water

- Up to 6 months between maintenance

- Multiple sensors – reduced cost

- Additional sensors of different types including pH, ORP and conductivity are available

The PeraSense peracetic acid measurement sensors and flow cells are available with different controllers giving you the same great performance with different communication, display, and peracetic acid dosing control options.

- Peracetic Acid Dosing Control

- Bottle Washers

- Rinsers

- Sea Water

- CIP Plants

- Drinking Water

Anywhere you have a requirement to measure residual CH3CO3H is a suitable application for PeraSense. The PeraSense peracetic acid monitor range is particularly suited to working in sites where reliability and ease of use are most important.

Why not click here and ask for a demonstration of all that our peracetic acid analysers can do for you?

Pi’s PeraSense peracetic acid sensors and flow cells are available with different controllers giving you the same great performance with different communication, display, and control options.

The whole range of PeraSense peracetic acid analysers can be fitted with additional sensors such as ORP or pH. Please ask your local distributor for more details.

The PeraSense peracetic acid analyser can be installed in a variety of auxiliary flow cells and self-cleaning devices.

Any questions?

Please contact us by using the form below.

| Document | Type | Size |

|---|---|---|

| PeraSense | Brochure | 663kB |

| PeraSense for Online Peracetic Acid Monitoring | Technical Note | 897kB |

| CRONOS® | Brochure | 712kB |

| CRIUS® | Brochure | 733kB |

| CRIUS® Remote Communications | Brochure | 669kB |

| CRONOS® and CRIUS® Control Options | Technical Note | 649kB |

| Remote Access GPRS | Technical Note | 593kB |

| Autoflush | Brochure | 411kB |

| Probe Fouling | Technical Note | 316kB |

Focus Ons are a series of short articles distributed by email providing technical information regarding instrumentation, process measurement in potable, waste, process and pool waters. If you would like to join the mailing list, please contact us.

Why is there a requirement for peracetic acid (PAA) online monitoring?

Common disinfectants such as chlorine and chlorine dioxide have been used effectively in water applications for over a century. Some industries however have looked to use other alternatives which have fewer or no considerations of safety and which don’t require residual or by-product removal. One of these alternatives, which has found increasing popularity across many industries, is peracetic acid (PAA). As more applications turn to PAA disinfection there has been an increase in demand for a reliable and accurate monitoring and dosing analyser.

Common disinfectants such as chlorine and chlorine dioxide have been used effectively in water applications for over a century. Some industries however have looked to use other alternatives which have fewer or no considerations of safety and which don’t require residual or by-product removal. One of these alternatives, which has found increasing popularity across many industries, is peracetic acid (PAA). As more applications turn to PAA disinfection there has been an increase in demand for a reliable and accurate monitoring and dosing analyser.

Process Instruments’ (Pi) PeraSense is a robust online analyser capable of continually monitoring and optimising the levels of PAA, providing you with the peace of mind that chemicals won’t be wasted and the water quality will never be compromised!

Did you know that…

… Pi’s PeraSense requires approximately ten minutes of maintenance, once every six months?

… Pi’s PeraSense is suitable for all potable, process and salt waters?

… Pi’s PeraSense amperometric sensor has up to a 15 year life span?

What is peracetic acid and why is it used?

PAA is a powerful oxidant with an oxidation potential, used as a measure of disinfection effectiveness, greater than that of common disinfectants such as chlorine and chlorine dioxide. It is produced by the reaction between acetic acid and hydrogen peroxide when dissolved in water, and degrades over time forming non-toxic water soluble products. The free radical degradants (bug killing species); hydrogen peroxyl and hydroxyl have high oxidising capacities and are generally believed to destroy bacteria via the protoplasmic oxidation mechanism resulting in bacterial cell wall disintegration. The safe degradation pathway and high oxidation properties make PAA a popular disinfectant for many applications and industries.

Not only does PAA have greater disinfection power when compared to other alternatives but there are also implications of using chlorine which PAA users do not experience.

Chlorination of water can be achieved using three chemical mediums; chlorine gas, calcium hypochlorite and sodium hypochlorite, all of which have proved useful in many applications.

There are, however, several factors which affect their viability and all three mediums have safety concerns which must be addressed, including; potential gas release, corrosive properties and stability under heat and sunlight. As a result of this, sites often spend considerable amounts of time and money implementing safety precautions such as the safe generation and storage of these chemicals.

Furthermore, chlorine reacts with natural organic compounds found in the water supply forming potentially harmful disinfectant by-products such as Trihalomethanes (THMs) and Haloacetic acids (HAAs). The potential health hazards associated with exposure to these by-products, particularly THMs, have resulted in extensive drinking water regulations across the developed world with a stipulation on regular monitoring of these compounds across the water distribution system. As PAA usage only results in non-toxic degredants, no further costs are incurred on instrumentation to monitor potentially harmful residuals or by-products.

Although PAA does still have some safety considerations, as with all disinfectants, it is widely accepted that storage, generation and stability is superior to using chlorine.

What are the typical applications PAA is used for?

PAA has been primarily used as a cleanser and disinfectant in the food industry since the 1950’s, particularly for fruit and vegetable washing due to its highly effective anti-microbial properties. All disinfectants applied directly to food must not leave harmful residual by-products, which is why PAA is so widely used in this industry around the world. Other industries in which the water cleanliness is  of paramount importance have also turned to PAA for disinfection including; agricultural, dairy processing, wineries, breweries and even cooling towers.

of paramount importance have also turned to PAA for disinfection including; agricultural, dairy processing, wineries, breweries and even cooling towers.

Pi’s work with H&M Disinfection – Food and Beverage Disinfection

H&M Disinfection have designed, manufactured and installed cleaning and disinfection systems for the Food, Dairy and Beverage industries since the late 1980’s, providing their customers with bespoke cleaning solutions specific to their clients needs. More recently, Pi and H&M Disinfection combined their experience and expertise in water quality monitoring instrumentation and disinfection process engineering respectively to supply a UK food processing plant with an optimum water treatment solution, capable of handling their peak process water demand to ensure the sites final water meets the industry’s strict regulations. Pi’s PeraSense analyser made up a small but integral part of the water treatment system provided by H&M Disinfection and continues to ensure the customer has optimum water quality.

Fundamentally, an effective PAA chemical dosing controller should allow the user to find the perfect balance between saving PAA and dosing enough for optimum disinfection and this relies on the quality of the instrumentation. Pi’s PeraSense is the complete PAA dosing controller which uses a state of the art two electrode amperometric sensor to provide the highest levels of accuracy for process PAA monitoring.

The controller provides the flexibility to ensure you have all the functionality you need and nothing which you don’t. The CRONOS® and CRIUS® controllers have up to two and four sensor inputs respectively, with the option of up to 16 sensor inputs with expansions on the CRIUS® meaning you can monitor multiple parameters from a single controller.

The PeraSense has the option to come with full PID and output controls, which are completely user configurable to provide the site with the ability to make the instrumentation suit their needs. Pi’s controllers can also offer the option for remote access, which provides site or servicing contractors the ability to remotely monitor the live levels of PAA, trend historic data, view system alarms, remotely configure settings and much more.

Many different sites ranging across the whole water industry have a daily struggle to keep instrumentation functioning correctly due to fouling. However did you know that…

… self cleaning and self flushing systems are now available from Process Instruments for most types of sensors?

… these fouling removal systems can extend the life of sensors and drastically reduce maintenance regimes?

… Pi’s self cleaning/flushing systems are affordable, simple and trouble free by design?

What is the problem?

Sensor Fouling

Whatever the process being monitored is, there is often something in the sample water capable of fouling a sensor, and therefore causing erroneous results. The obvious solution to this problem is to clean the sensor, but how regular should inspection and cleaning programs be for each piece of instrumentation? Too regular and the inspection and cleaning regime is time consuming and unnecessarily costly. Not often enough and the instrumentation will give false results and probably fail prematurely.

Whatever the process being monitored is, there is often something in the sample water capable of fouling a sensor, and therefore causing erroneous results. The obvious solution to this problem is to clean the sensor, but how regular should inspection and cleaning programs be for each piece of instrumentation? Too regular and the inspection and cleaning regime is time consuming and unnecessarily costly. Not often enough and the instrumentation will give false results and probably fail prematurely.

What is the solution?

Process Instruments’ Autoclean and Autoflush Systems

Simple, reliable and easy to maintain, Process Instruments’ Autoclean/Autoflush systems are an alternative to mechanical cleaning mechanisms which can clog and break. By regularly spraying the sensor/probe with clean water or air, the sensor remains clean and free from fouling for extended periods of time. The sensor cleaning cycle is activated by Pi’s controller for a user selectable length of time and frequency so that no matter how dirty the application, the probe remains clean. With no moving parts in the sensor body or in the cleaning attachment there is nothing to replace or check other than a simple valve positioned in an easy to reach location.

Pi’s Autoclean and Autoflush systems can give trouble free and fouling free functioning of sensors for weeks, if not months, at a time.

A solution for each application

Autoclean

This option can be added to our pH, ORP, Turbidity, Suspended Solids and Dissolved Oxygen (DO) sensors. Consisting of an end cap to direct the flow of clean water (or air for a DO sensor) across the face of the sensor blasting any dirt away. The cleaning is controlled by a single valve positioned in an easily accessible location.

Autoverify

If using air to clean a DO sensor the system can also automatically verify that the sensor is still responding correctly, removing any need to remove the sensor from the sample for months at a time.

Autoflush

For sensors that require flow cell mounting like Chlorine, Ozone and Chlorine Dioxide, an Autoflush system has inbuilt valves which automatically start/stop the sample flow and control the flow of clean water past the probe. The user can set the flushing interval and duration to keep the flow cell and sensor clear from fouling. For particularly dirty or stubborn contaminants, warm water can be used as the flush water to aid cleaning.

With the above options, whatever the application or parameter being measured, Process Instruments will be able to provide a monitoring system that will not only be accurate, precise and long lasting but that will also remain free from fouling and save the operator both time and money.